What is A Lathe Machine and How Does It Work - Machine Workss

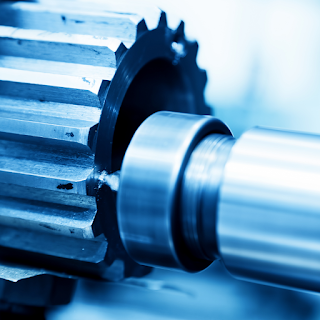

The CNC lathe is a machine tool that is often found in production lines. It can be used to make complicated shapes with great precision and detail, as well as more standard products such as bowls or speakers! A lathe machine is a common and often used machine tool that rotates a work piece by means of a tool applied to the work piece to perform various operations such as turning, facing, knurling, grooving. The function of the lathe is to machine round objects. The lathe processing process is to fix the pre-processed object and rotate it according to a fixed speed, and then use the tool to cut. Rotating the ongoing machining process, which is the lathe process, the finished product will be a perfect circle. The CNC lathe, full name Computerized Numerical Control Lathe, is a common and often used machine tool. The function of the lathe is to machine round objects. The lathe processing process is to fix the pre-processed object and rotate it according to a fixed speed, and then use t